Application

-

Battery materials

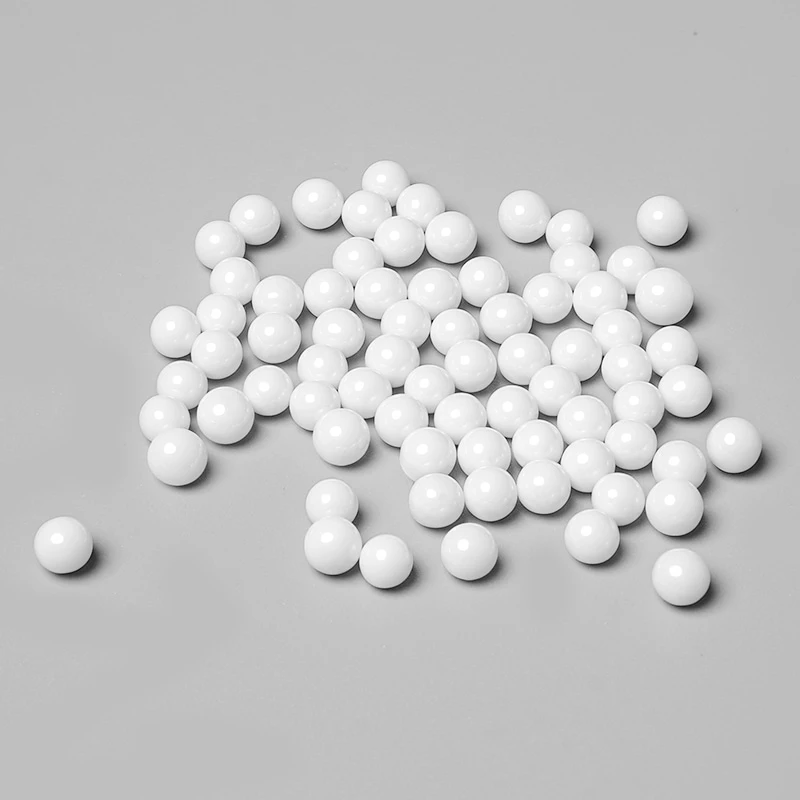

Used for grinding and superfine dispersion of new energy high-end materials such as Lithium iron phosphate cathode materials and silicon carbon anode materials. -

Semiconductor field

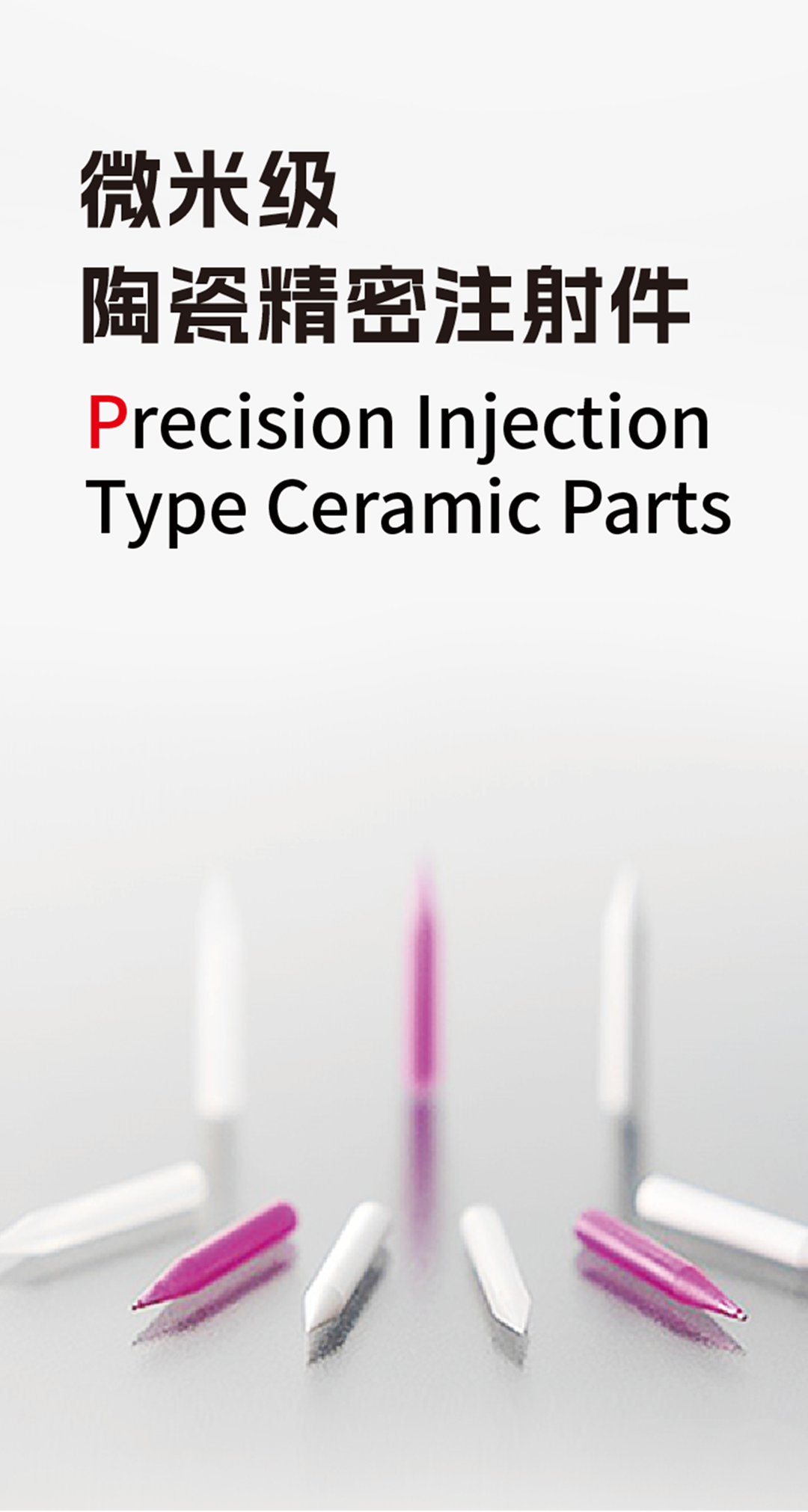

Chuangrui provides ultra wear-resistant grinding media, which can be used for grinding and ultrafine dispersion of electronic materials, magnetic materials, etc. in the semiconductor field; And precision ceramic injection parts such as ceramic cleats, filters, etc. -

Chemical machinery field

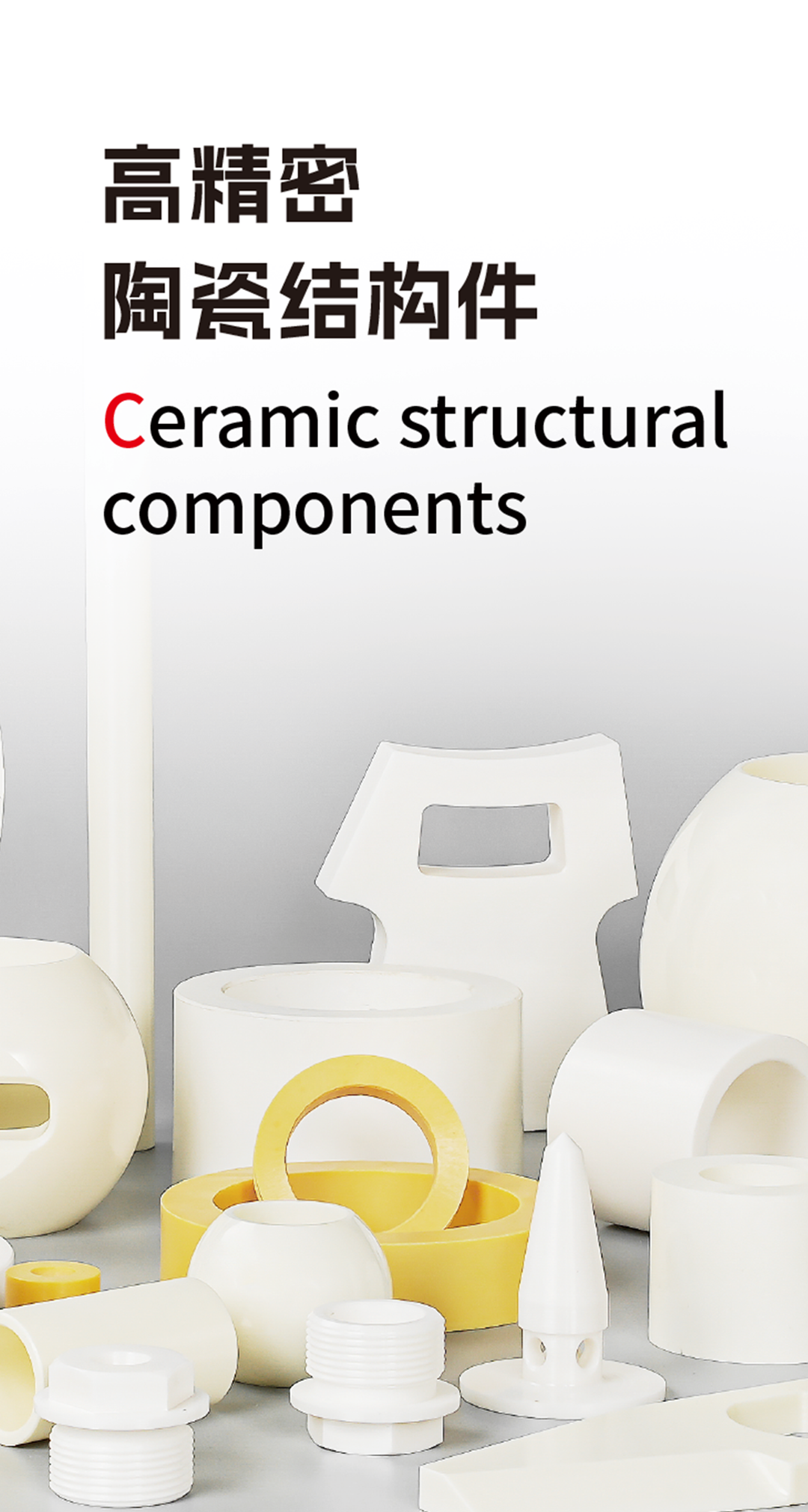

Chuangrui provides a variety of high-strength, corrosion-resistant, wear-resistant, and high-temperature engineering high-precision ceramic components, which can be used in various chemical, industrial, and engineering fields. -

Ink coating field

Grinding media can be used for grinding and ultrafine dispersion of paint, ink, and textile pigments.When using ceramic microspheres to grind dye particles or pigments, they are crushed to the micron level in suspension or dispersion, and partially to the nanometer level.

We are a professional manufacturer of high-performance ceramic materials and products.

In 1997, we were the first to launch zirconia beads in China. The company was formally established in 2006, focusing on "technical innovation, technical guidance, characteristic technology and mass production", and then successively independently developed and mass-produced product matrices such as nano zirconia beads and silicon nitride beads, zirconia ceramic structural parts, silicon nitride ceramic structural parts, composite ceramic components and micron precision ceramic injection parts, among which ceramic grinding media series products are unparalleled in solving the grinding problems of lithium battery materials, electronic materials, pharmaceutical products and paint ink.

-

Higher product performance

-

Greater processing capacity

-

Better technical support

Experiences of 28 years

News

View More

2025-12-23 15:08:15

High-Purity Zirconia Components for New Energy Material Processing | CRAC

Enable contamination-free manufacturing of lithium battery & PV materials with CRAC's high-purity 3Y-TZP zirconia components. Ensure product safety, extend cycle life, and boost product

2025-12-23 14:36:22

Wear-Resistant Zirconia Ceramic Parts for Extreme Conditions | CRAC

Solve abrasion and corrosion problems in mining, chemical processing with high-performance zirconia ceramic valves, wire drawing wheels, and plungers. 3-10x longer service life than tradition

2025-12-23 10:44:50

Zirconia Ceramic Components Selection Guide: A-ZR vs 3Y vs Yellow Zirconia

Choosing the right zirconia ceramic components? Our guide compares A-ZR(Y8), 3Y-TZP, and yellow zirconia series for wear resistance, corrosion resistance, and cost-effectiveness. Expert advic